Auto Clean

Equipment cleaning is often thought to be one step in the production process, however upon taking a closer look, it is an entire process to be developed and optimized on its own to maintain product quality & production output. There are many variables that impact equipment cleaning procedures for fluidized bed coaters, coating pans, and various blending equipment. This guide sheds light on cleaning procedure challenges for this equipment and how to address them

Manufacturing & production is the beating heart of any pharmaceutical company. These critical teams are responsible for meeting often demanding markets need and adhering to strict regulations, all without compromising productivity & product quality. These taske can often be demanding and overtly complicated to maintain, & the threat of an extended shutdown could mean loss of significant generated revenue. Having an

incorrect cleaning procedure for any pieces of pharmaceutical equipment can often be a root cause of these expensive shutdowns, specifically when it comes to the cleaning processes put into place for these equipment.

Every pharmaceutical cleaning procedure is unique and should be created based on the unique residues created and your cleaning capabilities. Without consideration of these variables.

Application:

PHARMA INDUSTRY

Auto Clean RMG Cleaning

AC.01R.20.001

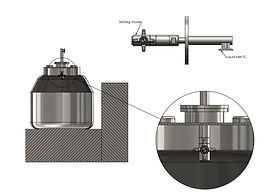

Auto Cleane FBP/FBD Cleaning

AC.01F.20.001

Auto Clean Blender Cleaning

AC.01B.20.001

FOOD/BEVERAGE INDUSTRY

Auto Clean Vessel/Reator

AC.01V.20.001

Auto Cleane Blender Cleaning

AC.01B.20.001

CHEMICAL INDUSTRY

Auto Clean Vessel/Reator

AC.01V.20.001